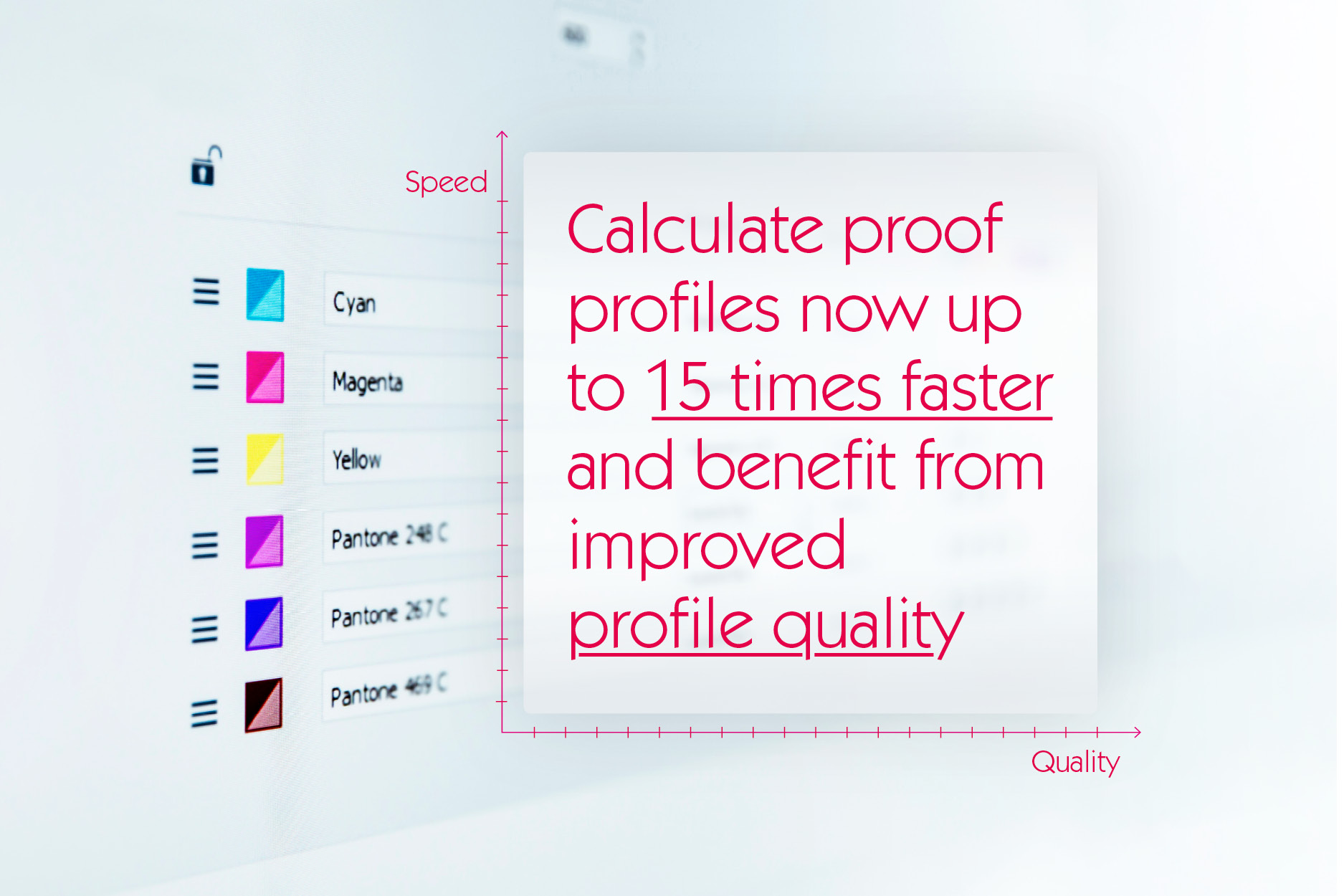

Precise simulations with spectral data

Our patented conversion technology enables color-accurate simulation – even without test charts. In addition to spectral color data, printing process, substrates and even ink sequence are taken into account. If a parameter changes, a profile can be quickly calculated without the need to run a new proof.